Add to Cart

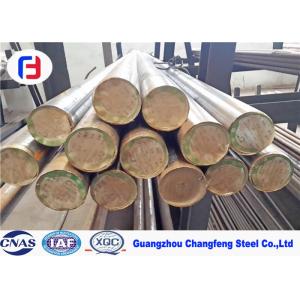

D2 Cold Work Tool Steel Round Bar for Cutting Tools and Measuring Tools

About D2 cold work tool steel

It is used for metal stamping die, drawing die, stainless steel blanking die, die blanking high hardness, cutting Daomo, Roll die, metal parts production, machinery manufacturing.

D2 cold work tool steel can be used to make large cross section, complex shape, strong impact, high resistance to cold working die steel, such as silicon steel sheet die, cold cutting scissors, trimming die, etc..

High wear resistance and micro deformation, cold working die steel, wind hard tool steel, carbon content up to 1.5%, chromium content high, noisy 11.5%, heat treatment, hardness up to 60 HRC.

D2 Cold Work Tool Steel Application:

For metal stamping die, drawing die, stainless steel sheet punching die, high hardness punching die, cutting knife mold, Roll Die, metal parts production, machinery manufacturing etc.

(1) Used for drawing die of refrigerator compressor rear cover, quenching hardness 56~58HRC.

(2) In order to improve the service life of flat rolling material for D2 cold working die, the wear resistance and impact toughness of steel are greatly improved by adding rare earth, so as to improve the service life of flat rolling material of round die.

(3) Because the content of V and Mo in D2 steel is higher than that of Cr12MoV steel, it has better comprehensive properties, and the traditional Cr12MoV steel will be replaced gradually.

(4) Made of D2 steel rolling wheels, from Taiwan palette die, and Cr12MoV can improve the service life of steel compared to 5 ~6 times.

Features:

A, Excellent machinability.

B, Excellent dimensional stability when hardened.

C, Good processing, heat treatment size stability.

D, After hardening and tempering, the high surface hardness match well with the toughness of the body.

Chemical composition (%)

| C | Si | Mn | Cr | Mo | V | P | S |

| 1.40-1.60 | 0.30-0.50 | 0.30-0.50 | 11.0-13.0 | 0.70-1.20 | ≤0.8 | ≤0.030 | ≤0.030 |

Similar grades:

| AISI | DIN | GB | JIS |

| D2 | 1.2379 | Cr12Mo1V1 | SKD11 |

Available Sizes:

| Flat Bar Size(mm) | Round bar Size(mm) | |||

| Thickness | Width | Length | Diameter | Length |

| 8-160 | 155-810 | 3000-6000 | 10-80 | 300-6000 |

Recommend heat treatment:

| Quenching | Tempering | ||||

| Heating temperature/℃ | Cooling | Hardness/HRC | Heating temperature/℃ | Cooling | Hardness/HRC |

| 980-1040 | Oil or Air | 60-65 | 180-220 | Air | 60-64 |

| 1060-1100 | 60-65 | 510-540 | Air | 60-64 | |

Terms of payment: 30% deposit T/T and the balance by L/C at sight, or T/T

Delivery condition: 15-35 days

Our Advantages

More photos