Add to Cart

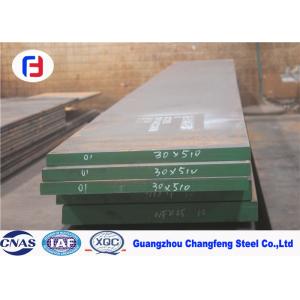

High Toughness, High Hardness Cold Work Tool Steel SKS3 O1 1.2510

SKS3 cold work tool steel is a high toughness, high hardness air-cooled hardened and high-chromium tool steel, it has better hardness and toughness than SKD steel.

SKS3 cold work tool steel known as "undeformed steel," but the formation of mesh carbide more sensitive. Mainly used for quenching requires deformation is small, long and complex shape cutting tools and measuring tools and high-precision die and so on.

Equivalent grades

| GB | DIN | AISI | JIS |

| 9CrWMn | 1.2510 | O1 | SKS3 |

Chemical Composition(%)

| C | Si | Mn | Cr | W | P | S | V |

| 0.90-1.05 | 0.15-0.35 | 1.00-1.20 | 0.50-0.70 | 0.50-0.70 | ≤0.035 | ≤0.035 | 0.05-0.15 |

Available size(mm)

| Flat Bar Size(mm) | Round Bar Size(mm) | |||

| Thickness | Width | Length | Diameter | Length |

| 6-80 | 205-610 | 2000-6000 | 12-180 | 300-6000 |

Recommend heat treatment

| Quenching | Tempering | ||||

| Heating temperature/℃ | Cooling way | Hardness (HRC) | Tempering temperature /ºC | Cooling way | Hardness (HRC) |

| 820-840 | Oil Cooling | 64-66 | 160-180 | Air Cooling | ≥62 |

Feature

(1) With excellent machinability, hardened, the size is extremely stable, hardened, the surface has a very high hardness.

(2) With a high toughness, so excellent anti-wear ability and easy forging and quenching.

(3) Can be widely used in cutting, cold stamping and forming tools; such as notch die, cold stamping die, various gauges, reamers, mold bushings and plastic small modules.

Applications

1. Used to create a large cross-section and complex shape of the cold die, and a variety of measuring tools.

2. Commonly used in punching die, stamping die, bending die, drawing die, punch punch, fine mold, and other metal molds.

Heat treatment specifications

* Quenching: first preheated to 550 ℃ ~ 650 ℃, and then heated to 800 ~ 850 ℃ hardened in oil.

* Tempering: heated to 150 ℃ ~ 200 ℃, stay in this temperature, and then quenched in still air cooling.

* Hardness: HRC60 ℃ above

* Annealing: heated to 750 ~ 800 ℃, at this temperature to stay for one to three hours, let the furnace to let it cool.

Delivery condition

1) EF or ESR, hot rolled or forged, black surface or milling.

2) For abundant stock, 15-20 days.For customized products, 30-50 days.

About Changfeng Steel

Guangzhou Changfeng Steel Co., Ltd is a mould steel stockist, we have our own mould steel factory and trading company. Our main steels are carbon tool steel, plastic mold steel, hot work tool steel, cold work tool steel, Hot Rolled alloy steel for mechanical, etc.

We provide all materials with high quality and competitive price.